The Intimidator™ 15XP is the ultimate 15″ capacity drum-style chipper thanks to an industry leading 37″ diameter drum and Bandit’s proven slide box feed system. The oversized drum turns at approximately 1,083 RPM, providing unmatched torque easily pulling large diameter material into the chipper. A larger diameter drum chips material requiring less horsepower and fuel while creating less vibration, making it one of the more popular machines available on the market today.

Key Features

15” capacity chipper

Engine options up to 165 horsepower

Largest diameter drum in its class

Industry leading performance and ease of use

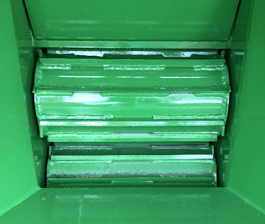

Powerful Feed System and Oversized Drum

With a large 37” diameter drum, most of the material is chipped on the bottom half of the drum with the grain, like a disc. The 15XP chips with limited vibration, consumes less fuel, and requires less horsepower than rival 15” capacity drum chippers in its class.

Heavy-Duty Chipper

The heart of a drum hand-fed chipper is the chipper drum and housing. The Intimidator™ 15XPs are equipped with:

• 37” diameter x 18-¾” wide drum

• 4 staggered knife pockets

(more cuts per revolution)

• 3-½ ” diameter chipper shaft at hub

• 2-15/16” pillow block chipper roller bearings

Built Tough

Bandit’s drum style chippers are known for their toughness, high performance and productivity. More than 6,000 Bandit hydraulic feed drum style chippers are in operation worldwide. Their ruggedness and dependability are keys to their popularity and high resale value.

Chipping Action

Note the difference between the cutting action of the drum in our 37” diameter drum style chipper compared to that of our leading competitors, which use drums approximately 22” in diameter. Notice that we are chipping on an arc with the grain, while they are often chipping into/across and against the grain.

Powerful Dual Feed Wheels

The Intimidator 15XP has 10-5/8” diameter x 18-3/4” wide feed wheels which 2,420 lbs. of pulling power for each feed wheel. The standard hydraulic lift cylinders adds another 3,480 pounds of hydraulic down pressure for the top feed wheels increasing production and reducing the amount of trimming required to process material. Operators are more productive and less fatigued.